Palletizer and Depalletizer Introduce

1、Depalletizer

In the beverage production line, the depalletizer's primary function is to automatically unload empty cans, glass bottles, or other materials stacked on pallets and transport them through the conveying system to subsequent inspection and filling processes. The automatic depalletizer for cans or glass bottles typically involves a forklift placing a pallet loaded with empty cans/bottles onto a pallet conveyor, which then transports it to the pallet lift table of the main machine. The pallet lift table raises the positioned empty can/bottle pallet to the unloading height, and after the cans/bottles are unloaded, the empty pallet is lowered onto the conveyor. Through mechanical devices and automatic control systems, the depalletizer lifts materials from the stack layer by layer and pushes them onto the conveyor chain, achieving the function of automatically unloading packaged materials!

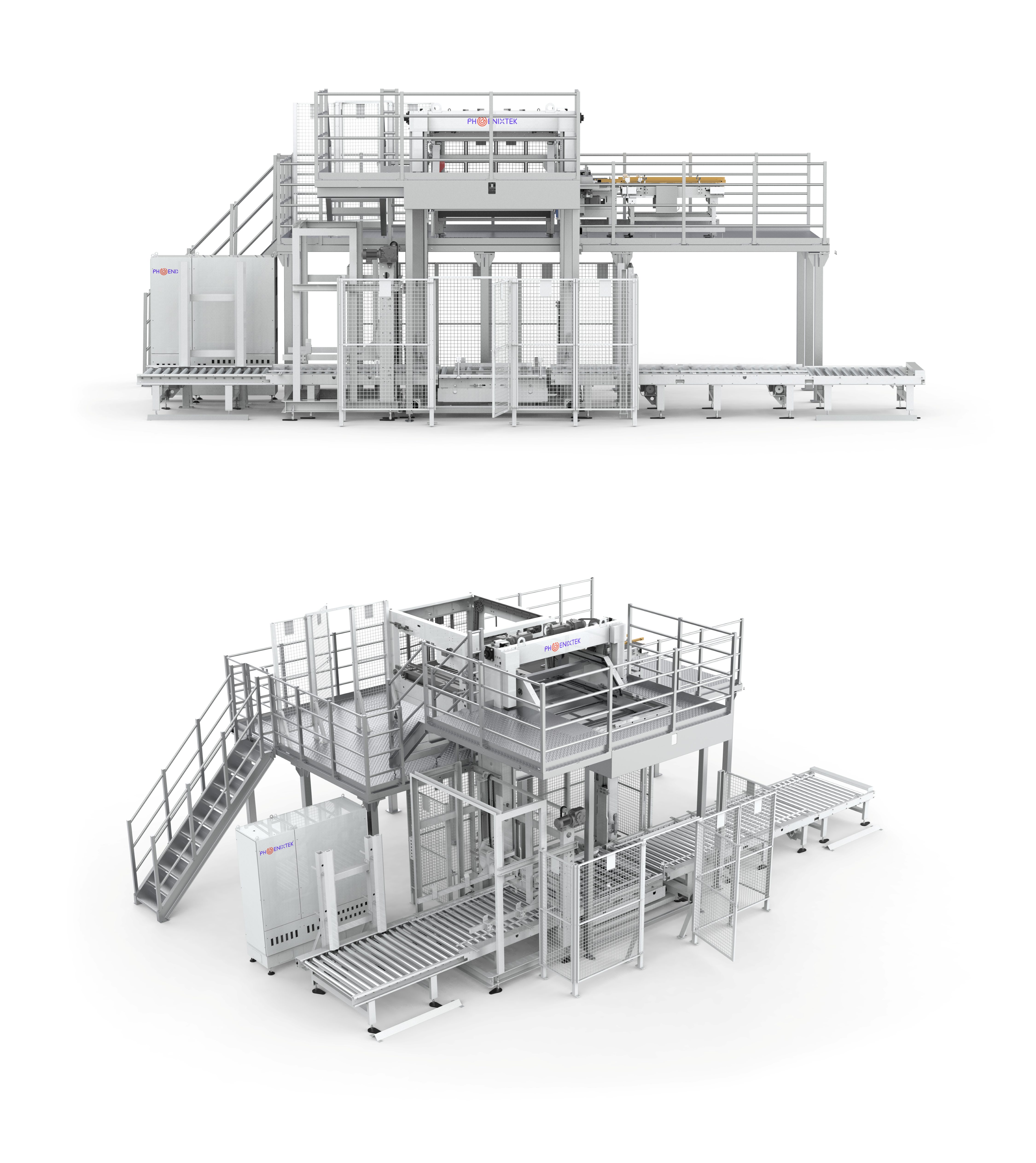

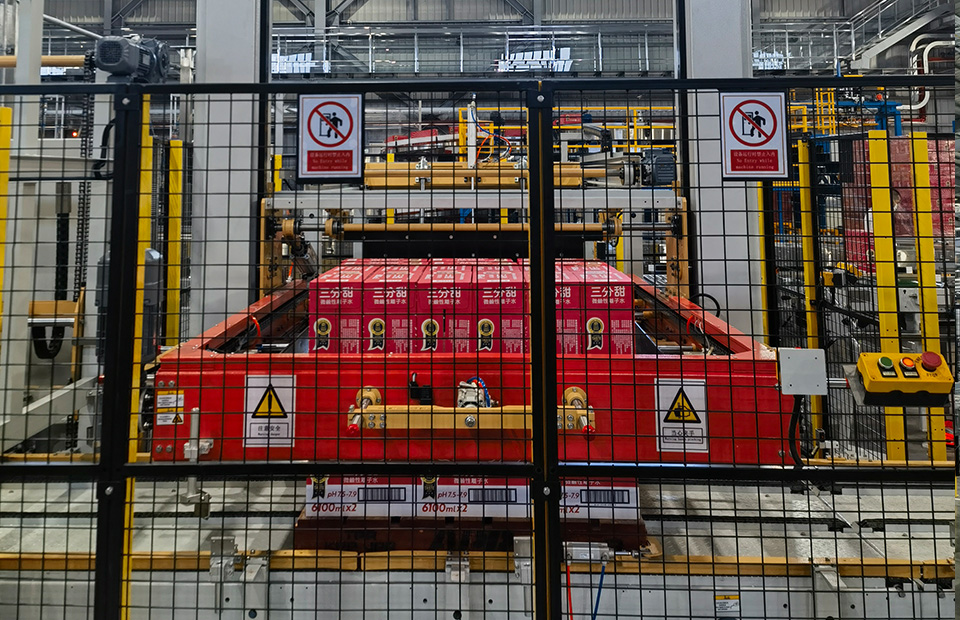

2、Palletizer

In the beverage production line, the palletizer is a crucial automated equipment used to arrange and stack filled products (such as cartons, film packs, etc.) onto pallets or trays in a specific pattern. This equipment significantly enhances production efficiency, reduces manual labor intensity, and ensures stable operation over extended periods. Modern palletizers can intelligently adjust and optimize based on different product requirements, improving the flexibility and adaptability of the production line. Additionally, many palletizers employ PLC + touch screen control for intelligent operation management, simplifying the operation process and reducing labor intensity. Currently, palletizers mainly include traditional gantry-type palletizers, robot-grouped palletizers, or fully robotic palletizers to meet the needs of various scenarios!

We offer customized unloading and palletizing equipment tailored to the specific needs of our customers.

.jpg)